NORTH 3DI

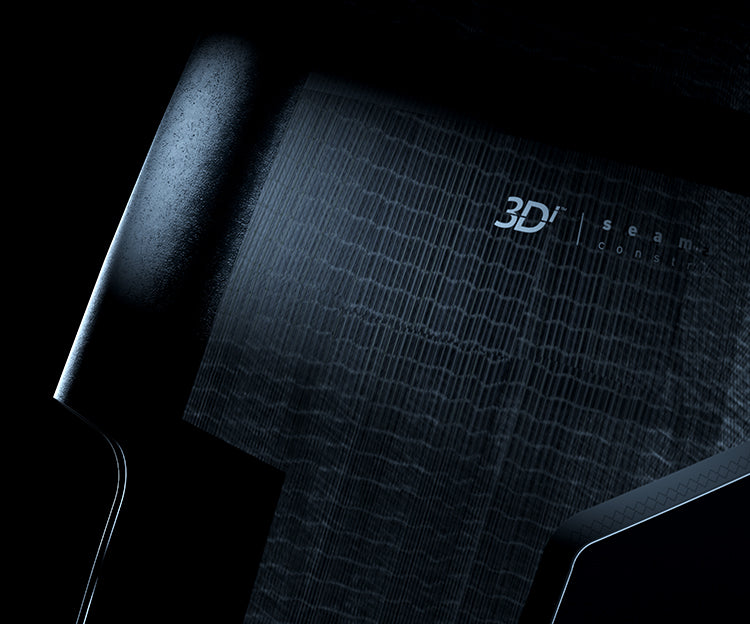

3Di molded

windsurfing sails

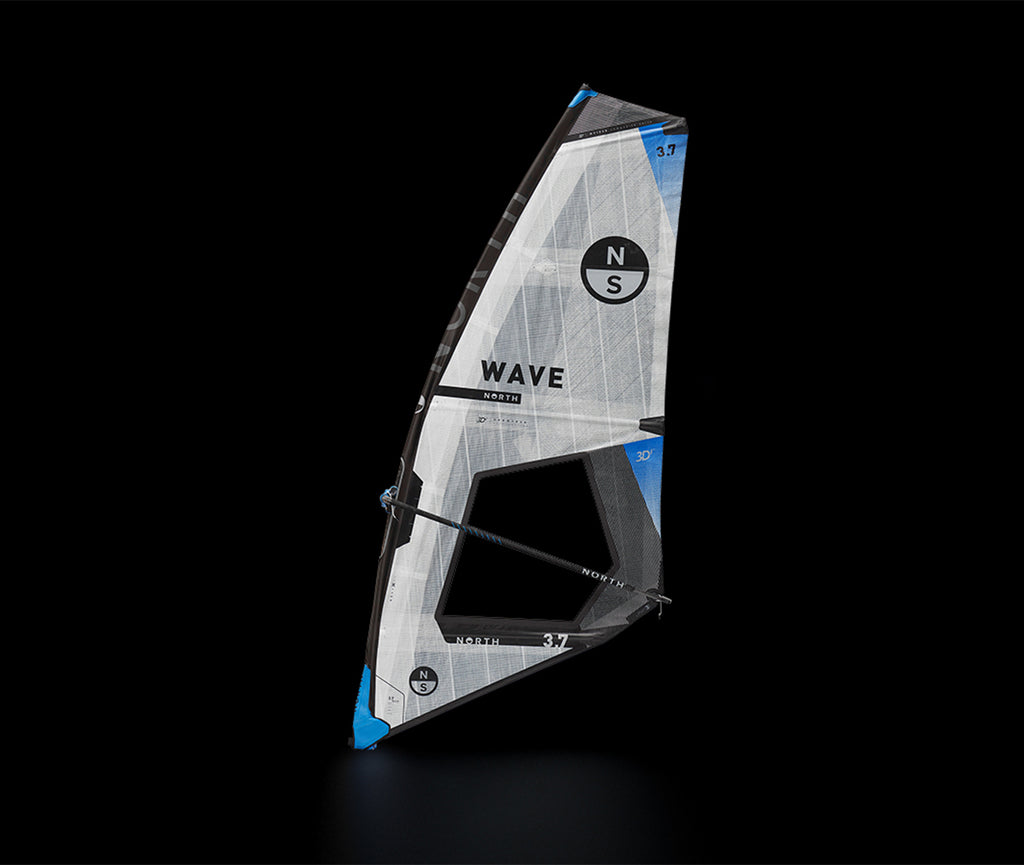

Thanks to 3Di technology, riders will have more confidence to push harder, higher and faster in both extreme conditions and lighter winds than ever before.

North Windsurfing and 3Di

North Sails 3Di exemplifies outstanding value with industry leading shape holding and a longer service life compared to any other sailmaking technologies today. Proprietary software, engineering and construction methods allow 3Di sails to maintain their shape to an unprecedented level. There’s a reason why Volvo Ocean Race teams trust 3Di mainsail for 45,000+ miles around the world. Solo ocean racers are even circumnavigating the globe with 3Di sails for multiple laps. 3Di sails also have a lower cost of ownership than any other sail in the world.

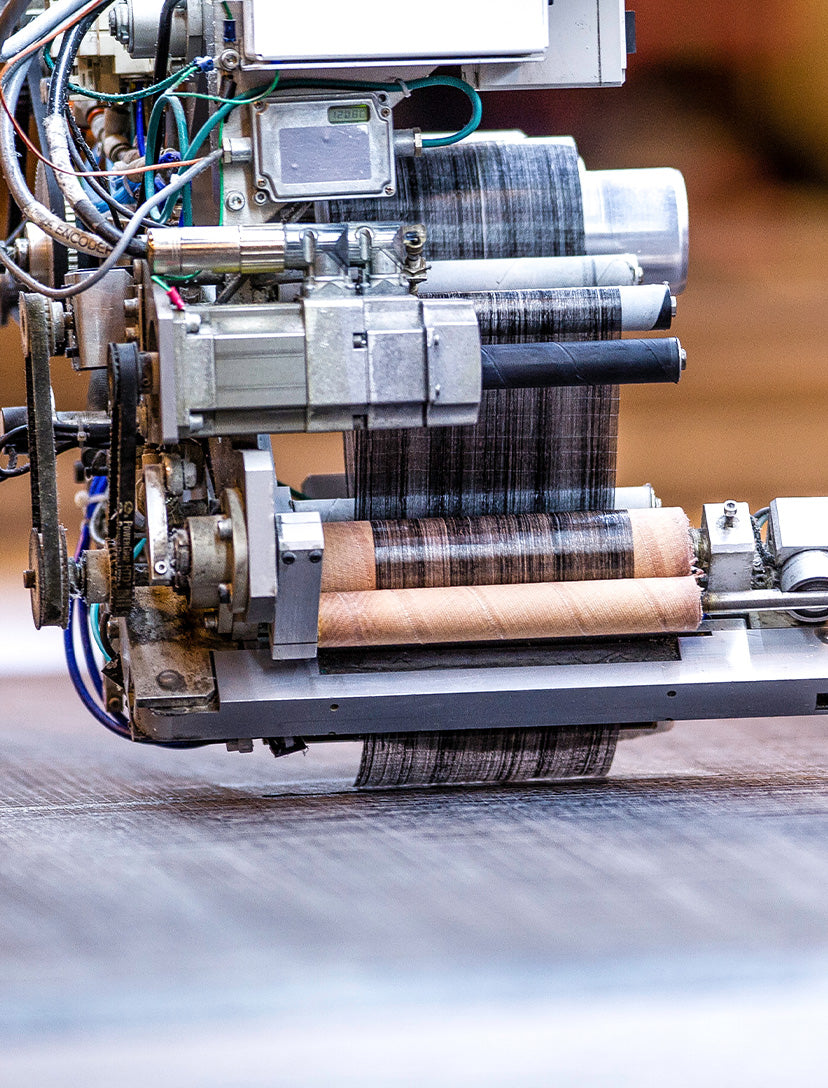

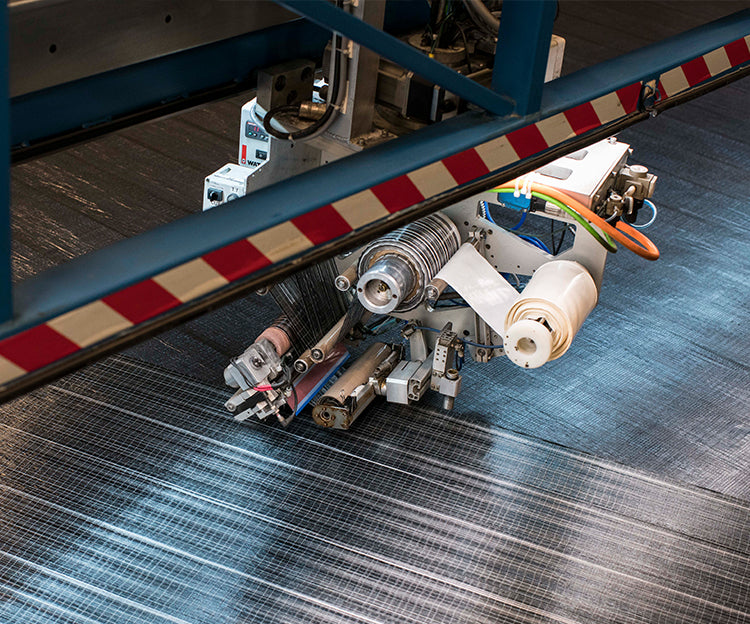

3Di sails are significantly stronger and lighter than our competitor’s Laminate string sails. North Windsurfing is the only sailmaker who utilises ultralight unidirectional filament tapes to build sails from materials in their most basic elemental form.

3DI Features explained

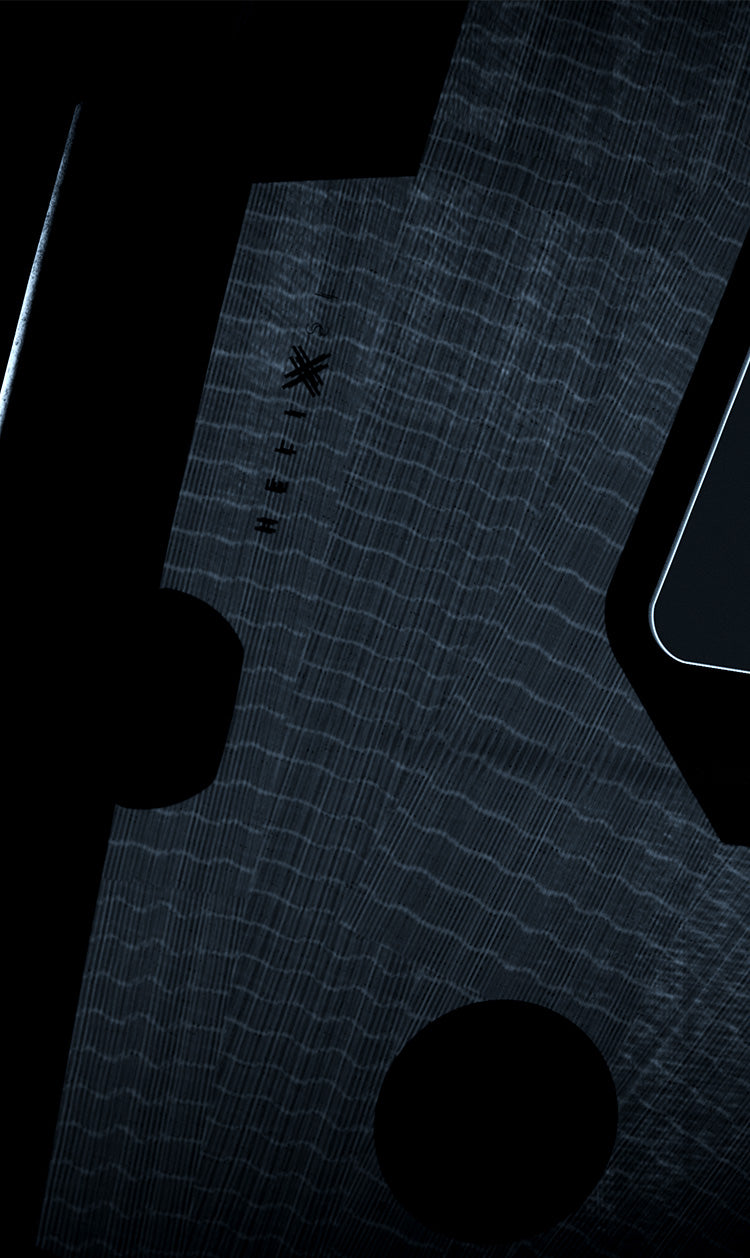

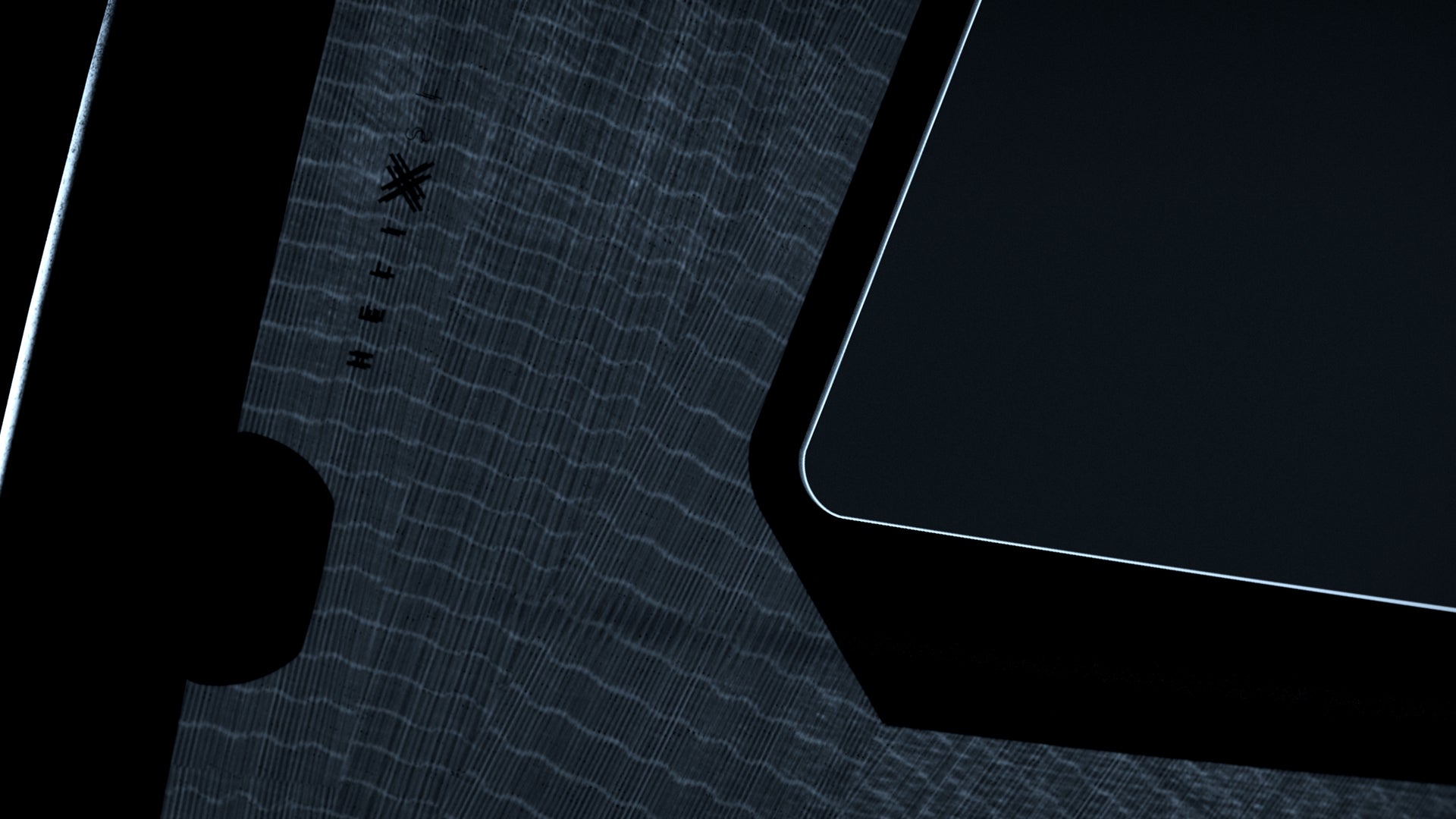

The skin of the sail is the base of everything. This is where our 3Di technique comes into play. 3Di is built up from 5 sub features which are all incorporated and executed in one single production system. This allows us to create a three-dimensionally shaped sail from one single piece instead of the conventional sections cloth panels from batten to batten or panel to panel.

By gradually changing fiber density throughout the skin we made sure load and impact requirements are being met. This is the result of shaping the entire skin of the sail in 3D, eliminating the limitation of shaping under battens, which leaves you with the only windsurfing sail on the market that has a 100% shaped surface.

If this hasn’t gotten you excited yet, keep in mind that 3Di is used in making sails for the Volvo Ocean Race and the America’s Cup.

3Di MOLDED COMPOSITE 3Di™ Thermo-formed Sail

Molding the sails in 3D determines the shape, which means we can add shaping or twist in the sails without being limited to batten position.

3Di allows us to position fibers only where it’s truly needed resulting in a sail that’s 30-40% lighter than what you’re used to. It’s mesmerizing to see how one 3Di skin can transition seamlessly from thicker parts, to hold tension and resist impact, to other areas in the sails which are thinner, lighter and softer.

Dyneema Aramid

3Di sails are composed out of material that we feel is right for the job. To cover the entire Isotropic Layer of the sail we’ve chosen tapes of Dyneema Aramid fibers. By layering these tapes of fibers, we can incorporate different functions and parts into the sail, without breaking it up into different panels.

Integrated Reinforcements

Sandwiched around the Isotropic Layer you will find more Dyneema Aramid. In high load and impact areas, we have multiple layers stacked on top of each other at a multitude of angles, creating an impact-specific Fiber Layout to compliment the Isotropic Base Layer. This creates the most lightweight, strong, and durable sail ever built.

Load Specific Tape Layout

3Di helps direct the tension throughout the sail to give it the best dynamic stability. By creating an uninterrupted Isotropic Fiber Layout integrated with the load specific tape layout, we can control and redirect the tension in the sail. This load specific tape layout will give a sail optimum performance.

Integrated Batten Pockets

In between all the aforementioned layers we use a special material, machine laid in, to create the batten pocket. The material bonds to the Dyneema Aramid fibers but doesn’t bond onto itself. This leaves the sail with a 100% uninterrupted and fully integrated tunnel with space for the batten.

WAVE

View collection

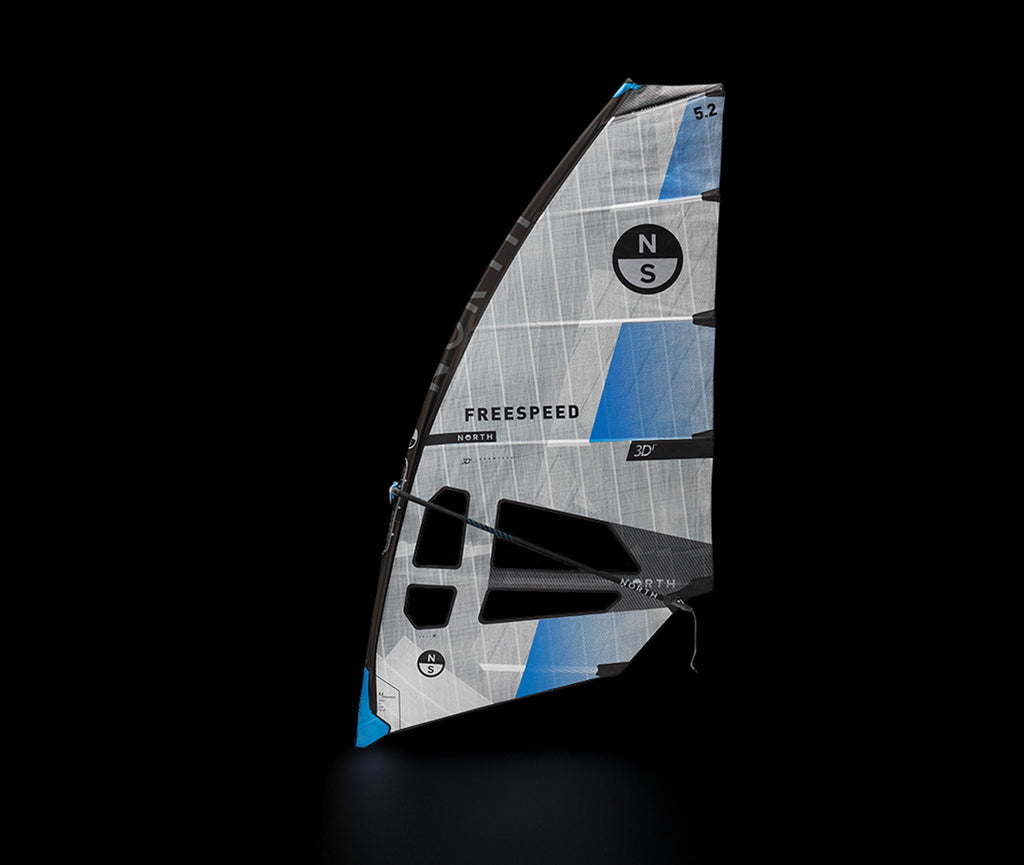

FREESPEED

View collection