Hi Hugh, thanks for chatting to us! How did you get into kiting?

I had been following the winters between New Zealand and USA snowboarding when a mate from Engineering school came back from a trip to New Caledonia and had got into kiting. His sales pitch to me was how would you like to jump six times higher than you ever have in snowboarding big air and land softly in the water. Before long we were planning a trip to Aitutaki in the Cook Islands for him to teach me to kite. Upon return, I brought my own Naish Aero 10m kite but didn’t have the finances to buy a board also. My local kite store told me that we had an innovative kiteboard manufacturing company here in Christchurch New Zealand called Underground Kiteboarding, so I approached them to work for free for a couple of weeks to learn how to make my own board.

You spent some of your early kiting days in Christchurch, New Zealand. What was the scene like there at the time?

The Christchurch Kiteboarding scene was going off in 2003 with so much stoke for the sport on and off the water. We had great role models in international kite boarder Kane Hartell and then women’s world champion, Cindy Mosey. The innovation in Underground kiteboard manufacturing was spurred along by local legends Steve Palmer and Aaron Smith. Two weeks turned into two years and working in each stage of kiteboard manufacturing was super cool. The factory was situated right on the estuary with butter flat water and once the wind monitors in the lunchroom hit 18 knots, we were all out on the water, of course making up for work later that evening.

You now live in Raglan which has one of the world’s premier left-hand surfing waves. What is it like for kiting there and for equipment testing?

Kiting, winging, and prone foiling are a dream in Raglan. With a rocketing outgoing current, you can add six knots to the wind strength. So even with a breath of wind, when you jump in the outgoing current, you’re well-powered. The harbour is great for testing foils, and doing freestyle or big air twin-tipping you tend to jump just to stay downwind. Catch the current out towards the bar and you can choose either left or right hand waves. Oh, I mean nah Raglan’s crap, always requires a wetsuit, far too cold hahaha.

You’re also a ninja on a skateboard and mountain bike… Can you tell us the secret to eternal youth?!

Whatever you do, don’t stop or you won’t start again. Oh, and try to keep up with your kids.

What was your route into your current role in the wind sports industry?

I completed a Bachelor of Mechanical Engineering in 2002. Then as above, got practical work experience making kite boards, travelled the world kiting in Maui, South America, Europe, and down to Cape Town for a season working in retail and doing kite lessons. I then got an Accessories Designer job with Ozone which turned into a Product Management role for 5 years. Then I designed control systems and hardware for Cabrinha and harness components for Neil Pryde for another 5 years. Which lead to co-founding the new North Kiteboarding and North Foils brands 5 years ago.

“I wear two hats at North, one overseeing the look, feel and direction of all North products with the senior management team and another working as more of an industrial design engineer, mainly on hardware projects.”

- Hugh Pinfold

What is your official job title at North and which products are you focussed on?

My official title is the Director of Design and Engineering at North. I wear two hats at North, one overseeing the look, feel and direction of all North products with the senior management team and another working as more of an industrial design engineer, mainly on hardware projects. I am one of the industry’s most experienced kite control bar designers, having designed five control systems from scratch, and many iterations in between over the past 15 years. I also enjoy designing twintip bindings, boots, foil board straps, kite inflation systems and various other moulded products.

What’s been the proudest moment of your design career?

The Navigator Pro is the product I am most proud of because it pulls together so many features I dreamed of implementing in a control bar. However, the proudest moment would have to be when we first showed off the new North product range to our International Sales Team in Dakhla, in 2019. I have never worked so hard as we did to get that first range to market in just over a year. By the time we came out of the sales presentation and looked out on the water, over one hundred North kites were racing around the harbour. Wow, now that was a sight etched firmly in my memory.

"The Navigator Pro has been made 20% stronger whilst weighing 20% lighter. It features an exceptionally reliable auto unwinding system."

- Hugh Pinfold

Our test team really liked the original Navigator control system and are excited to get their hands on the new Pro version! How long have you been working on it and what was the design brief?

I’ve been working on the Navigator Pro for about three years now. Our design brief was to incorporate an auto-unwinding front-line system whilst creating the safest most intuitive control system on the market.

What are the main technical upgrades over the Navigator?

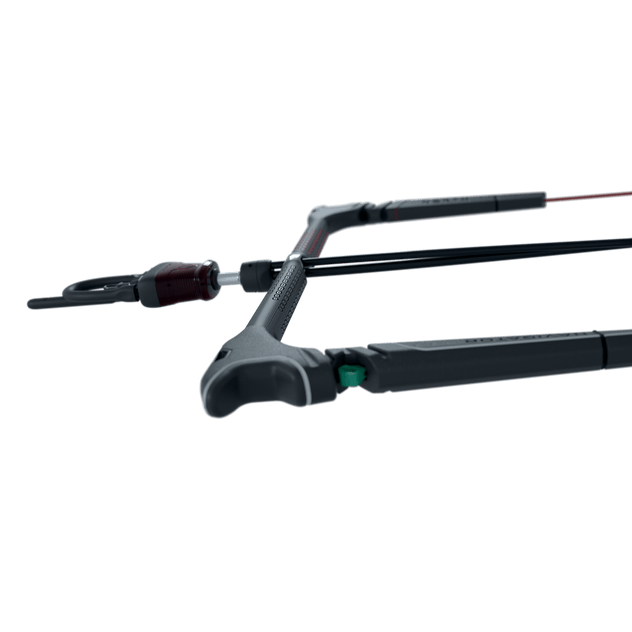

The Navigator Pro has been made 20% stronger whilst weighing 20% lighter. It features an exceptionally reliable auto unwinding system. The Quick Release (QR) has been redesigned to be even safer, with special attention to reduce both accidental QR release or accidental harness loop unhooking. However, the feature I’m most proud of is the super comfortable feeling bar grip. We’ve invented a new compound grip formula that is softer for ultimate comfort, with micro texture that provides fantastic grip when dry, wet, hot, or cold. This grip is also three times more wear resistant and utilizes a premium internally stitched construction.

Will the Navigator bar continue to run as a product? If so, who should choose the Navigator Pro over the standard Navigator?

For sure. The classic Navigator bar will continue to run for those who prefer the joy of simplicity and don’t mind manual control of their front lines. The Navigator will also remain at a lower cost price.

The Navigator Pro is for those that love having the highest performance control bar as their cockpit. A couple of notes, you do have to connect the correct front left and right lines to the kite with an auto unwinding bar – this connection is highlighted by the red power ball on the left when running your lines out. With more moving parts on the auto unwinding Navigator Pro, you do also need to be more vigilant with cleaning the bar in fresh water after each use.

“The Navigator Pro is for those that love having the highest performance control bar as their cockpit.”

- Hugh Pinfold

What makes ceramic bearings more suitable for a marine application?

Ceramic bearings have excellent corrosion resistance in marine environments. Ceramic bearings are rounder, smoother and harder than steel. Ceramic also has a lower density which makes them lighter weight.

What technology is hidden under the grip?

Under the grip is our one-piece composite over-moulded truss bar. This construction was the breakthrough that allowed us to both increase strength and reduce overall weight.

The centrepiece, through which the two high-quality individual PU tubes run, is injection moulded from stainless steel for ultimate strength and dimensional stability. A Titanium PVD coating aids the smooth sheeting in and out and is super hardwearing. This simplifies the bar design with no need for replaceable central inserts.

The Navigator Pro should work universally across many different brands. What features have you implemented to enable this?

As with the current Navigator, we use line connectors on the ends of our flying lines that are all the same length. Therefore, if you have a non-North kite that has the kook-proof knotted connectors on the tips of the kite (rather than the inner bridles) you can easily exchange them from the front to rear lines to seamlessly work on either configuration.

Navigator bars are designed to work with any low-V kites, including all North kites from 2020 onwards. However, we also offer an easily retrofittable high-V split connector accessory kit should your non-North kite be set up to fly best with a high-V split in your front lines.

And finally, can you give us any hints about what you’re working on now?

All I can say is that it sure would be a pity to not use some of these great new Navigator Pro technologies in the next generation of the Navigator…

FAQ

What is it the grip diameter?

The grip diameter is 26mm, the same as the Navigator control system. Other brands use a smaller diameter, however we find this gives the rider more fatigue over time. With multiple prototypes with a range of diameters, 26mm feels like the golden number.

Will the PU tubes crack?

Hey there, great question. The PU tubing we use on the Navigator Pro is a very specific grade with excellent abrasion resistance and with UV additives that we especially import to be extruded for us. We have been testing with this tubing for hundreds of hours over two years now and haven’t had any split or fail. On test bars with over 100 hours use, the PU tubing does become a bit more matt ie. the gloss finish gets sanded a little. If you were to use regular PU tubing, wear and splitting may be an issue.

What is the length of the Freeride Loop?

The new Pro standard Freeride Harness Loop is just 1cm longer than the 23 Navigator Short Freeride Loop. As it is folded over this will only equate to 5mm of difference which I doubt you will notice. The reason we reduced the size of the standard harness loop that comes with the Nav Pro bar is that the industry is more about Big Air now and not so focused on unhooking anymore. For Big Air, most people want the most secure connection, which happens to be a smaller loop. For the remaining Freestylers amongst us, you can still easily trade out for the large freestyle loop for easy unhooked riding. The new Security Finger on the Nav Pro has also made it a lot more secure for accidental unhooking.

How is line shrinkage with the affect uneven shrinkage between front and back lines?

With our testing over the years we have found the thinner 1.3mm rear lines, which are under much less load, don’t shrink as much over time as salt crystals, sand and debris get into the weave. As they are smaller they will also stretch a little more under load. Note the 1.3mm SK99 rear lines are still ample strong enough with a big safety factor even with wear taken into account at 325kg. We’ve kept the front lines at 1.55mm SK99 with a breaking load of 490kg. The Nav Pro does feature up to 10cm of line adjustment should you still need to adjust the bar lines over time. We have tested lines from most manufacturers and particularly as the coating wears off all lines have some degree of shrinkage over time.

How’s does the titanium coating help durabilty?

The centrepiece on the Navigator Pro bar is made with a new technology injection-molded Stainless Steel which creates a very strong and hard wear-resistant surface. On top of this we also coat the stainless steel with a Titanium PVD coating which is also very wear resistant and helps the bar slide freely on the PU tubing. In all our hundreds of hours of pre-production testing over the last two years, we have not experienced any bar centrepieces getting sharp. I suspect rider concerns around bar centrepieces getting sharp were perhaps alluding to Aluminum or regular cast Stainless Steel.

How durable are the bar inserts?

Bar inserts are generally made from plastic which has a much softer less durable surface hence need replacing every so often. We made it our mission to design a bar centrepiece that would not wear out and get sharp over time. From our hundreds of hours of on water testing with test riders of all abilities from beginner to pro we have not seen any of our centrepieces get sharp from excessive wear.

Why split the lines as a 12m+10m? Why not 20m+2m?

That’s a good question and it’s one that we’ve debated heavily within our product development team. With everything you offer there are compromises and it’s impossible to please everyone. On the North Navigator bars the spliced loop-to-loop join also acts as a stopping point when you deploy your QR. 12m is long enough distance to completely depower our largest kite but not too far so you end up with a pile of spaghetti-twisted flying lines, which is more likely to happen with the stopper up higher. There are some people foiling and doing short line kite loops with 12m lines, however these are mostly used by schools teaching with limited space on their local beaches. We did debate having 12 + 8 + 2m also but if you can imagine there are small tolerances that come into manufacturing with splicing joined lines and the more joins you have, the more space you create for discrepancies between lines. The main clincher is that 99% of people never adjust their line lengths and are happy to just ride the 22m lines that come as stock. Note you do get 2m line extensions with the Orbit Pro kite, and we offer line accessory packs in 2, 6, 8, 10, and 12m lengths if you really want to tweak your setup. I hope this helps to follow our rationale.